Selecting the appropriate power source for your electronic devices requires careful consideration of various factors, particularly when evaluating modern energy storage solutions. A lithium polymer battery represents one of the most advanced and versatile options available in today's market, offering superior performance characteristics compared to traditional battery technologies. Understanding the key specifications, applications, and selection criteria will help you make an informed decision that meets your specific power requirements while ensuring optimal device performance and longevity.

Understanding Lithium Polymer Battery Technology

Core Technology and Construction

The fundamental design of lithium polymer battery technology utilizes a solid polymer electrolyte instead of the liquid electrolyte found in conventional lithium-ion cells. This construction method allows for greater flexibility in cell shape and size, enabling manufacturers to create custom form factors that fit specific application requirements. The polymer electrolyte provides enhanced safety characteristics by reducing the risk of electrolyte leakage and thermal runaway events that can occur with traditional liquid-based systems.

Manufacturing processes for these advanced cells involve layering cathode and anode materials with the polymer separator, creating a flexible and lightweight power source. The absence of a rigid metal casing allows for thinner profiles and reduced overall weight, making these batteries ideal for portable electronics and space-constrained applications. Advanced quality control measures ensure consistent performance across production batches, with cycle life ratings often exceeding 500 charge-discharge cycles under normal operating conditions.

Performance Characteristics and Advantages

Energy density represents one of the most significant advantages of lithium polymer battery technology, typically delivering 150-250 Wh/kg compared to 100-150 Wh/kg for nickel-based alternatives. This superior energy-to-weight ratio translates to longer runtime periods between charging cycles, crucial for mobile devices and portable equipment. Additionally, these cells maintain stable voltage output throughout the discharge cycle, providing consistent power delivery to sensitive electronic components.

Temperature performance characteristics demonstrate excellent stability across a wide operating range, typically from -20°C to 60°C for most commercial variants. Low self-discharge rates, usually below 5% per month, ensure stored devices retain their charge for extended periods. The ability to customize voltage levels by connecting multiple cells in series or parallel configurations provides designers with flexibility to meet specific power requirements without compromising overall system efficiency.

Key Selection Parameters

Capacity and Voltage Requirements

Determining the appropriate capacity rating requires analyzing your device's power consumption patterns and desired operating duration between charges. Capacity specifications, measured in milliampere-hours (mAh), directly correlate to the total energy storage capability of the cell. For applications requiring extended runtime, higher capacity variants provide longer operation periods but typically result in larger physical dimensions and increased weight.

Voltage compatibility ensures proper integration with existing electronic circuits and charging systems. Standard lithium polymer battery cells deliver 3.7V nominal voltage, with fully charged levels reaching 4.2V and discharge cutoff typically set at 3.0V. Understanding these voltage parameters prevents potential damage to sensitive components and ensures reliable operation throughout the entire discharge cycle. Multiple cell configurations can achieve higher system voltages when required by specific applications.

Physical Dimensions and Form Factor

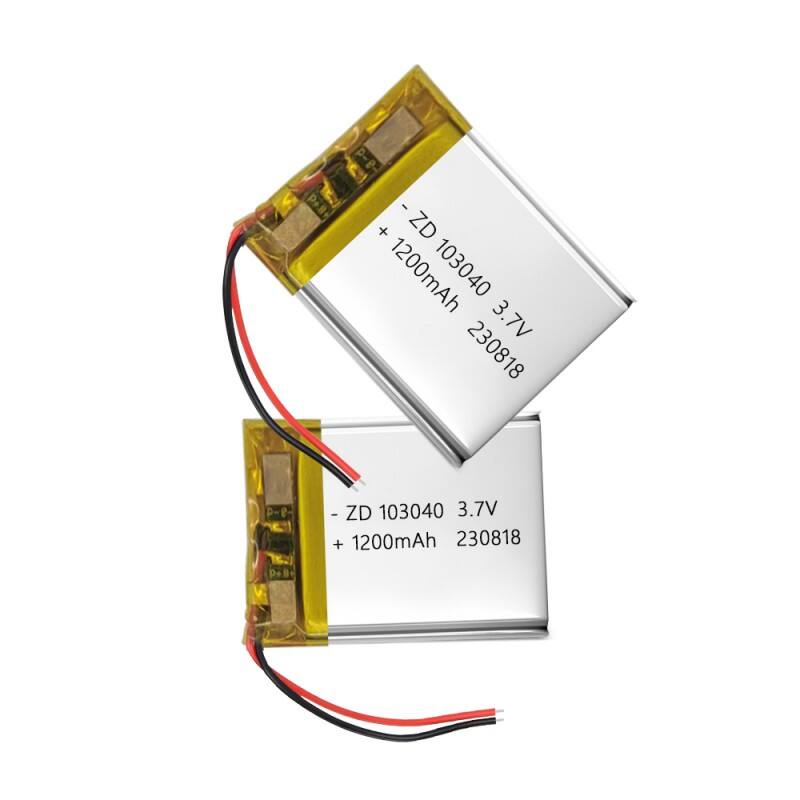

Space constraints within your target application significantly influence battery selection decisions, as physical dimensions must accommodate available mounting areas while maintaining proper clearances for thermal management. Standard industry dimensions follow specific naming conventions, with numbers indicating thickness, width, and length measurements in millimeters. Custom form factors can be manufactured for unique applications, though standard sizes typically offer better availability and cost advantages.

Weight considerations become particularly important for portable devices where every gram affects user experience and device handling characteristics. The flexible nature of lithium polymer battery technology allows manufacturers to optimize thickness and shape to maximize capacity within given dimensional constraints. Proper mechanical mounting methods ensure secure installation while preventing damage from vibration or impact forces during normal operation.

Safety and Protection Features

Built-in Protection Circuits

Modern lithium polymer battery systems incorporate sophisticated protection circuit modules (PCM) that monitor critical parameters including voltage, current, and temperature during charging and discharging operations. These integrated circuits prevent overcharging conditions that could lead to cell damage or safety hazards, automatically disconnecting the battery when voltage levels exceed safe thresholds. Over-discharge protection maintains cell integrity by preventing deep discharge conditions that can permanently damage the internal chemistry.

Current limiting functions protect both the battery and connected devices from excessive power draw that could cause overheating or performance degradation. Temperature monitoring capabilities shut down the system if internal temperatures exceed safe operating ranges, preventing thermal runaway conditions. These protection features operate transparently during normal use while providing essential safety barriers against misuse or system malfunctions.

Thermal Management Considerations

Effective thermal management ensures optimal performance and longevity of lithium polymer battery systems, particularly in high-power applications or elevated ambient temperature environments. Proper ventilation around the battery compartment allows heat dissipation during charging and discharging cycles, preventing excessive temperature buildup that can accelerate aging processes. Thermal interface materials can improve heat transfer between the battery and device chassis when necessary.

Operating temperature ranges specified by manufacturers provide guidelines for safe installation environments, with performance characteristics varying significantly outside recommended limits. Cold temperature conditions may temporarily reduce available capacity, while excessive heat accelerates chemical aging and shortens overall service life. Understanding these thermal relationships helps optimize system design and installation practices for maximum reliability.

Application-Specific Considerations

Consumer Electronics Integration

Consumer electronics applications benefit significantly from the compact form factor and lightweight characteristics of lithium polymer battery technology, enabling sleeker device designs without compromising functionality. Smartphones, tablets, and wearable devices utilize custom-shaped cells that maximize available internal space while providing sufficient power for demanding processing requirements. Integration with device charging circuits requires careful attention to charging protocols and communication interfaces.

Power management systems in consumer devices optimize battery performance through intelligent charging algorithms and dynamic power scaling based on usage patterns. These systems extend overall service life by preventing stress conditions and maintaining optimal charge states during periods of non-use. User interface elements provide real-time feedback on battery status, remaining capacity, and estimated runtime under current usage conditions.

Industrial and Commercial Applications

Industrial applications often require enhanced durability and extended cycle life compared to consumer electronics, necessitating careful evaluation of battery specifications and expected operating conditions. Manufacturing equipment, monitoring systems, and backup power applications benefit from the reliable performance characteristics of lithium polymer battery technology. Environmental factors such as vibration, humidity, and temperature variations must be considered during the selection process.

Maintenance requirements for industrial installations typically emphasize long service intervals and predictable replacement schedules to minimize operational disruptions. Battery management systems provide detailed monitoring capabilities that track performance trends and predict maintenance requirements before failures occur. Documentation and certification requirements for industrial applications may specify particular safety standards or performance criteria that influence battery selection decisions.

Cost and Lifecycle Analysis

Initial Investment Considerations

Purchase price represents only one component of the total cost equation when evaluating lithium polymer battery options for specific applications. Higher-quality cells with enhanced protection features and extended cycle life ratings often provide better long-term value despite higher initial costs. Volume purchasing agreements and standardization on common form factors can reduce per-unit costs while simplifying inventory management and replacement procedures.

Development costs associated with custom battery solutions may be justified for high-volume applications where optimized performance or unique form factors provide competitive advantages. Standard off-the-shelf options typically offer faster time-to-market and lower engineering costs for prototype development and small-scale production runs. Supplier qualification processes ensure consistent quality and reliable supply chain relationships for critical applications.

Long-term Value Assessment

Total cost of ownership calculations must include factors such as cycle life, maintenance requirements, and disposal costs over the expected service period. Lithium polymer battery technology typically provides 3-5 years of useful service life under normal operating conditions, with gradual capacity reduction over time rather than sudden failure modes. Planning for end-of-life replacement and recycling requirements ensures environmental compliance and sustainable operations.

Performance degradation patterns help predict replacement schedules and budget for ongoing operational costs throughout the product lifecycle. Energy efficiency improvements from advanced battery technology can offset higher initial costs through reduced charging frequency and lower electricity consumption. Warranty coverage and technical support services from reputable manufacturers provide additional value and risk mitigation for critical applications.

FAQ

What is the typical lifespan of a lithium polymer battery

A lithium polymer battery typically provides 300-500 complete charge-discharge cycles before capacity drops to 80% of original specifications, translating to approximately 2-4 years of normal use depending on charging patterns and operating conditions. Factors such as temperature exposure, depth of discharge, and charging practices significantly influence actual service life. Partial discharge cycles and avoiding extreme temperature conditions can extend operational lifespan considerably beyond minimum specifications.

Can lithium polymer batteries be safely transported and shipped

Lithium polymer batteries can be safely transported when properly packaged and declared according to international shipping regulations such as UN3480 and UN3481 standards. Batteries must be protected against short circuits, secured against movement, and packaged in approved containers with appropriate hazard labels. Airlines and shipping companies have specific requirements for lithium battery shipments that must be followed to ensure safe transport and regulatory compliance.

How should lithium polymer batteries be stored when not in use

Optimal storage conditions for lithium polymer batteries include maintaining approximately 40-50% charge level in a cool, dry environment between 15-25°C with low humidity. Extended storage at full charge or completely discharged states can accelerate aging and reduce overall capacity. Periodic charging every 3-6 months during long-term storage maintains cell health and prevents deep discharge damage that could render the battery unusable.

What charging methods work best with lithium polymer batteries

Lithium polymer batteries perform optimally with constant current/constant voltage (CC/CV) charging methods that prevent overcharging while minimizing charge time. Smart chargers that monitor cell voltage and temperature provide the safest charging experience by automatically adjusting charge rates and terminating when full capacity is reached. Avoid using chargers not specifically designed for lithium polymer chemistry, as improper charging can cause safety hazards and permanent damage to the cells.